Leicester Fire Department Leicester, MA

PORTFOLIO| Contractor Builder Systems Inc. |

| Client Leicester Fire Department |

| Business Type Government • Fire Department • Hospitality • Medical Facilities |

Project Overview

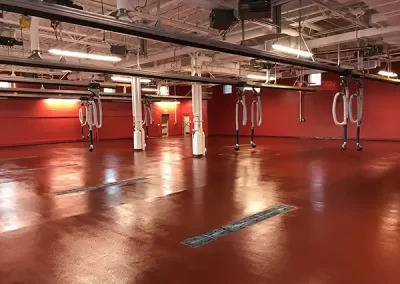

Leicester Fire Department contacted us towards the end of 2017 looking for a durable floor for their new apparatus bay. The Chief and others from the town met Dan at the Stow Fire Academy, where the Hybri-Flex EB system had previously been installed by Northeast Flooring. The high moisture tolerance and thicker, self-priming and self-leveling floor system was a great option for the newly poured concrete floor in the Leicester Fire and EMS apparatus bay. On top of the system’s high moisture tolerance, it is also both impact and slip resistant which are not only desired but imperative for the happenings at the station. We also installed Mighty Lines Floor Tape in white to help provide a visual separation of the bays and provide guidance when parking the different vehicles inside Photo Credit to Tim Drew of Cobb Hill ConstructionMaterials

- Dur-a-Flex Hybri-Flex EB system